MAKING BETTER CONNECTIONS

NON-WELDING PIPE

CONNECTION TECHNOLOGY

Swaging is the controlled uniform reduction of the fitting end over the tube whereby forces are applied equally 360 degrees around the fitting. The result of swaging creates a permanent connection between the fitting and tubing by plastically deforming together as an assembly.

BONLOK is a purely cold-work, non-welding pipe connection technology that is at least 10 times faster than welding.

It eliminates the need of X-Ray NDT and hot-work during pipe connection for a safer, faster and cleaner working environment.

STANDARDS

Temperature range: –50 °C up to +600 °C

Working pressure: up to >1000 bar

Standards: Useable for seamless and welded pipes

MATERIALS

Press Ring and Fitting Body: Carbon steel, Stainless steel, Duplex; other materials available upon request

PIPE DIAMETERS

½" to 6" (Outside diameter in inch)

DIMENSIONING OF THE WALL THICKNESS

The dimensioning of the pipes is done to DIN 2413 or to ANSI B 31.3 for a given pressure for the particular application. For further specifications consult the pipe manufacturers.

Driver moves Press Ring to closed position, compressing fitting body onto pipe wall.

High compressive load on pipe from sealing rings creates gas tights double seal.

Dynamic load between pipe and BONLOK fitting delivers enhanced joint integrity to resist in-service Flex, Vibration and Pull-out loads.

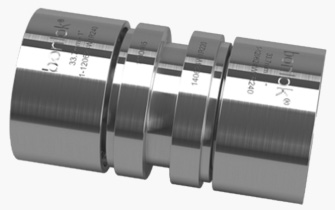

Straight Coupling / Reducer

Straight Coupling / Reducer

45° & 90° Elbow

45° & 90° Elbow

Tee / Reducing Tee

Tee / Reducing Tee

Flange

Flange

Threaded

Threaded

Distributor

Distributor

Other types of fittings and custom made are available upon request

The BONLOK 100% metal to metal joint is a direct replacement for welded joints, providing a superior alternative to most alternative pipe connection systems. The assembly process eliminates the human variation so often found in alternative systems, producing an identical and perfect result every time. With no re-work and guaranteed long term reliability, the BONLOK quality saves you money.

Preparation for the perfect connection is a simple and fast process. Uncomplicated “Fit/No Fit” tools are supplied ensuring the right fitting for the pipe. Pressing each side of the BONLOK fitting takes as little as 15 seconds. Faster installation saves you time and money.

Often saving weight requires a sophisticated solution with elevated costs. With BONLOK, specifying pipe to the pressure requirement of the system, rather than the thickness necessary for the welding process, gives the opportunity to reduce the total weight of steel required, cutting down the cost for the piping. Saving weight saves you money.

In many environments fire or explosion is a real concern. The BONLOK connection does not generate heat or sparks and so the high pressure swage technology is not classified as how works.

Comparing the BONLOK system with a flanged joint system. There is considerable scope for reduced spacing between ceilings and deck. Reducing overhead coordination space has saved cruise ship designers tons of weight, impacting displacement and vessel stability, ultimately saving the operators money.

The BONLOK system allows you to assemble and install a piping system without finally pressing the fittings. The visual indication that a fitting is not pressed is an excellent feature for production and QC purposes which also allows for greater flexibility in production scheduling. Having flexibility in your production schedule, considerably saves time and money.

More than 1.5 millions BONLOK Fittings had been installed in more than 15 countries around the world.

BONLOK has the broadest range of fittings, across a wider size range to be sure we can provide you with a complete solution. BONLOK fittings are used in critical systems and therefore testing the technology comprehensively to its limits has been an essential element part of the development of the technology, the products and the company.

We have spent over US$1,000,000 on outsourced testing to simulate the most demanding and extraordinary conditions that BONLOK fittings might be subjected to in service.

BONLOK fitting technology is the third generation of the Haener Axial Press Swage Ring (HAPS) Joint, originally developed by Gottfried Haener who is the Senior Technical Advisor to the BONLOK

The extensive performance testing programme has resulted in BONLOK successfully securing the Type Approvals and product performance Certification necessary for use in many industries with pressures in excess of 400 bar. The certification process is ongoing as we respond to customer requests to enable the selection of BONLOK fittings for an ever wider range of applications

BONLOK South East Asia

7 Temasek Boulevard #12-07 Suntec Tower One Singapore 038987

Thank you for your time. We will be in touch with you as soon as possible.